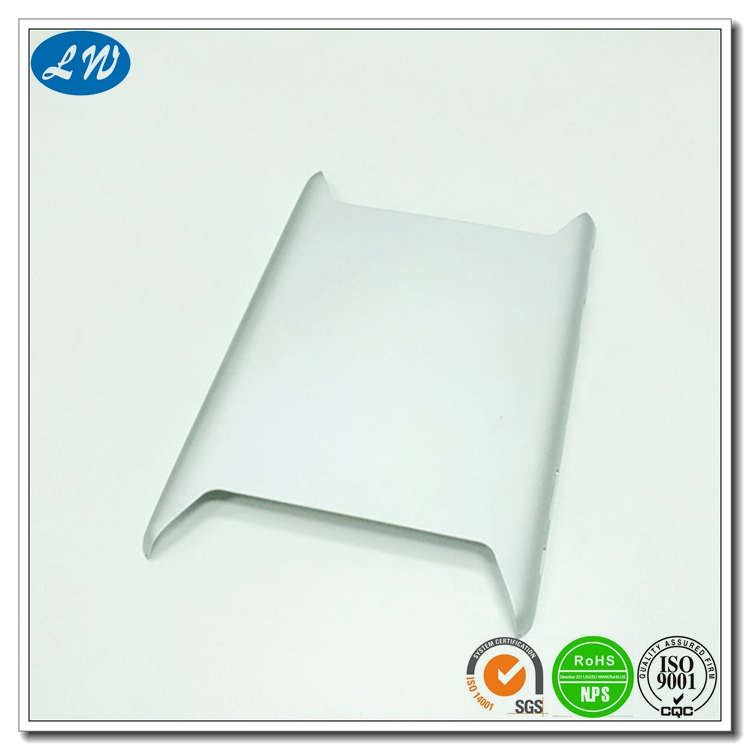

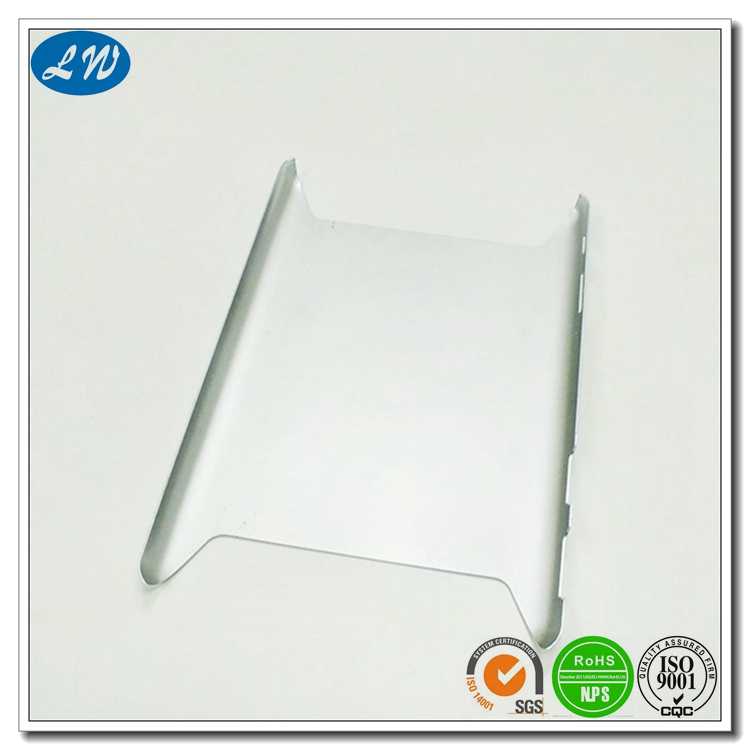

Stamping precision aluminum sheet parts laptop case

- Packaging:

- wooden box, pallet, carton, PVC tray, PP bag as the customer required.

- Brand:

- OEM

- Transportation:

- Ocean,Land,Air

- Place of Origin:

- China

- Supply Ability:

- 10000 / week

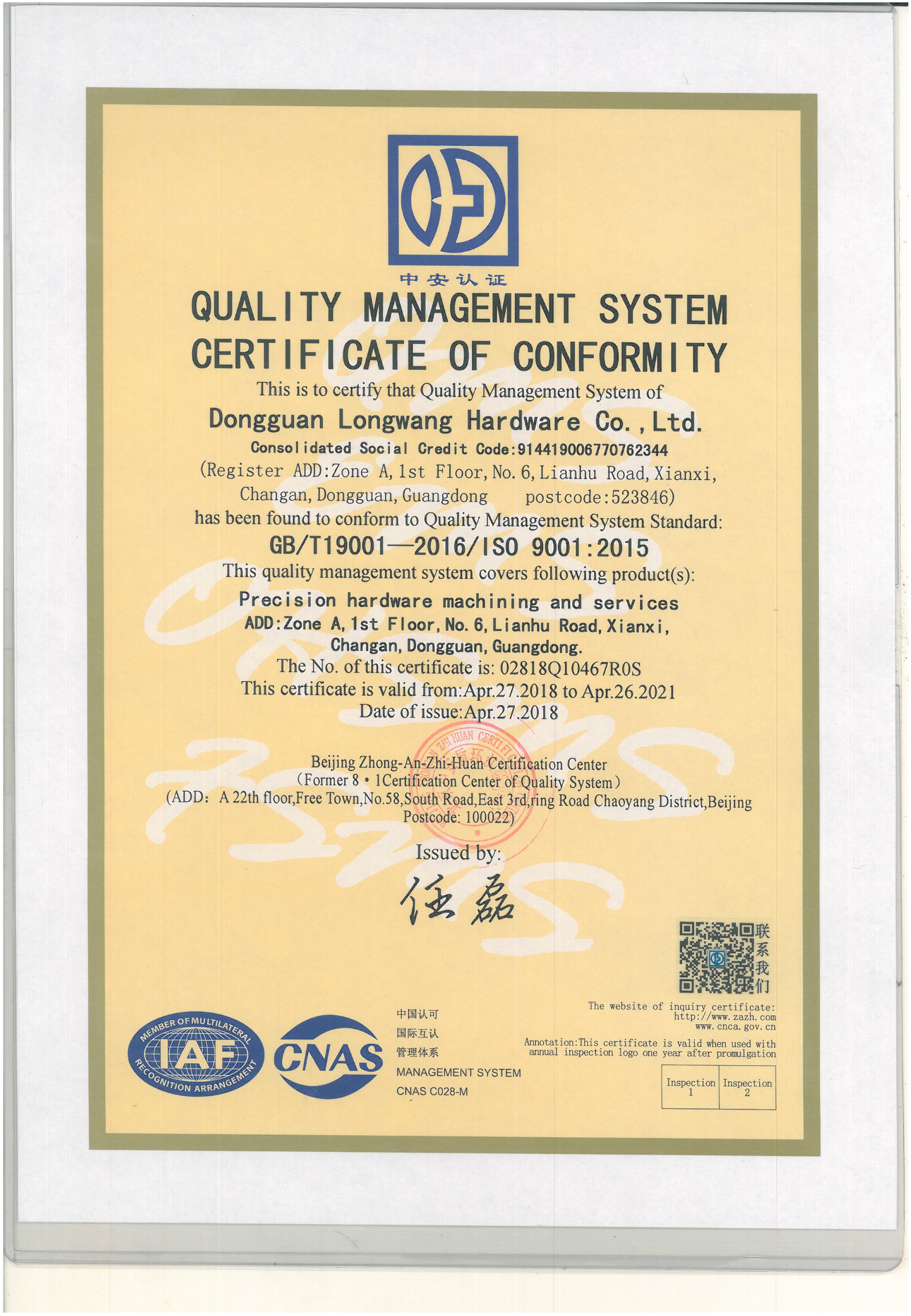

- Certificate:

- ISO9001:2015

- Port:

- Shenzhen,Guangzhou

Basic Info

Model No.: OEM

Product Description

Stamping also know as pressing,is the process of placing flat sheet metal in either blank or coil form into a stamping press where a tool and die surface forms the metal into a net shap.And metal stamping can be applied to variety of material s based on their unique metalworking,Idustries metal stamping is used for automotive,commercial,construction,medical,plumbing and 3C products.

Product Description

Featured Products

1. Materials: Steel,stainless steel,aluminum alloy,engineering plastics,copper,brass,bronze alloy are available.

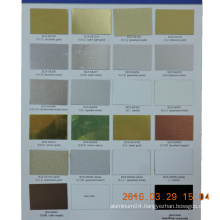

2. Surface treatments are available: Polishing,anodize, zinc plating, nickel plating, powder coating, e-coating,chome.

3. Advanced inspection equipments for rigorous quality and control and precise specification.

4. We are a direct manufacturer, have lots of experience for packing machine parts and medical parts.

5. Customizing inspection report, providing the material certification.

6. All sorts of drawing formats are available. For example: Pro/E , solid works, Cimatron, AutoCAD and so on.

7. Young manage team with efficent productivity ,quick response and modern business concept.

Specification

| Item | Aluminium heat sink part cnc machining service |

| Model | Heat sink-001 |

| Materials | Steel,stainless steel,aluminum alloy,engineering plastics,copper,brass,bronze alloy are available |

| CNC Turning: | Dia: 1to 300mm Length: 1 to 1100mm |

| Milling | 600x600x1100mm |

| Surface Treatment | Zinc Plating, Nickel Plating,Chrome Plating,Passivation,Hardening, High Frequency, Clear Anodizing, Black Anodizing,Black Oxide Coating,Degreasing,Brushing |

| Inspection | Caliper / Microscope / Micrometer / Concentricity Tester / Projector / High Gage / Roughness Tester etc. |

| Certificate | ISO |

| MOQ | 10 pcs |

| Price | USD1~10/pc |

| Lead Time | Within 30 working days |

With box, carton, wooden, pallet in regular and packed as clients' requirements

Payment

---Payment terms: Western Union, T/T,L/C

---Please remember to leave the correct contact information for delivery.

Shipment

---Shipping terms: DHL, UPS, FEDEX, TNT, EMS

---Dispatch would be arranged within 3 working days, once the payment is confirmed.

---Port is Shenzhen .

Sample Fee: Negotiate

Samples: Available for evaluation before place order.

Sample Time: 2-4 days

How To Order

1.We need the drawing,quantity and the sureface treatment which will be used on the product.

2.Discuss all details with you and make the sample if needed.

3.Start the mass production after getting your payment(deposit).

4.Send goods to you.

5.Receive the goods in your side.

Trade

- Your inquiry will be replied within 12 hours.

- Well-trained & experienced sales can reply your inquiries in English.

- During working time, E-mail will be replied to you within 2 hours

- The order will be produced exactly according to order details and proofed samples. Our QC will submit inspection report before shipment.

- Your business relationship with us will be confidential to any third party.

- Good after-sale service.

Company Information

| Factory Size (Sq.meters): | 1,000-3,000 square meters | |

| Factory Location: | wusha Industrial Port, changan County, guangzhou City, guangdong Province, China | |

| No. of Production Lines: | 5 | |

| Number of R&D Staff: | Less than 5 People | |

| Number of QC Staff: | Less than 5 People | |

| Certifications: | ISO9001 | |

| Contract Manufacturing: | OEM |

Equipment

FAQ

|

For more information pls visit our homepage: www.dglongwang.com

Product Categories : Precision Stamping Parts